27-06-2012, 09:15 AM

27-06-2012, 09:15 AM

|

#1

|

|

Senior

Join Date: May 2011

Location: Brighton East sussex

Posts: 985

Bike: 50 & stock xr70

|

How to valve your own pitbike shock

Found this while trawling the net and thought i might share

Hope somepeople find it usefull

- so in this thread, im going to teach everybody how to VALVE their own pitbike shock. do all this at your own risk and i recommend trying it on a china shock before you step up to taking your elka shock apart. shocks differ in pistons, valving, construction, air, nitro, oil, coatings. everything. i come from a background of valving big bike forks and shocks and this thread will teach you how to get a crappy shock and make it ride like a dream shock. takes lots of patience and figuring out so PLEASE be patient. i mastered motors, anodizing, powder coating, tire changing (changing around 50 tires a day at the old shop i worked at) and porting, ISF transmission treatments, i do it all. suspension was one of the most confusing and hard to learn things. but im gonna take it easy on you all and help you figure this out. note you WILL need valving shims which can be purchased from suspension shops only. also 99% of all suspension shops will tell you to go to hell when you ask to buy single shims. the only known place (by me) that will sell singles shims is rg3. each shim runs about $1.25 a piece. they are located in anahiem california and i just drive to the shop and pick them up but you can have them mailed. or call a local suspension shop and ask if you can purchase single shims, they might attack you (literally) on why you wana valve your own and not have them do it so be prepared. so shall we begin?

step one: dissasemble shock. china shocks come apart like a walk in the park. higher end shocks are more difficult and i wont be teaching you on how to do that, taking apart a high end shock MUST be done by somebody experienced so dont do something stupid with your brand new piggy back elka okay? my china shock (from ebay) is very easy. loosen the spring preload rings. then at the bottom of the shock is a washer with a cutout slot. slide the washed over the spring and through the shock shaft. removes spring and preload rings.

okay now you will be letting the air or nitro out of your shock. point it into a cup and release the air (oil may shoot out)

next you will begin with removing the shock seal and shaft holder. my china shock is simple, clamp the shock body, clamp the holder and apply elbow grease to loosen

okay now you will be letting the air or nitro out of your shock. point it into a cup and release the air (oil may shoot out)

next you will begin with removing the shock seal and shaft holder. my china shock is simple, clamp the shock body, clamp the holder and apply elbow grease to loosen

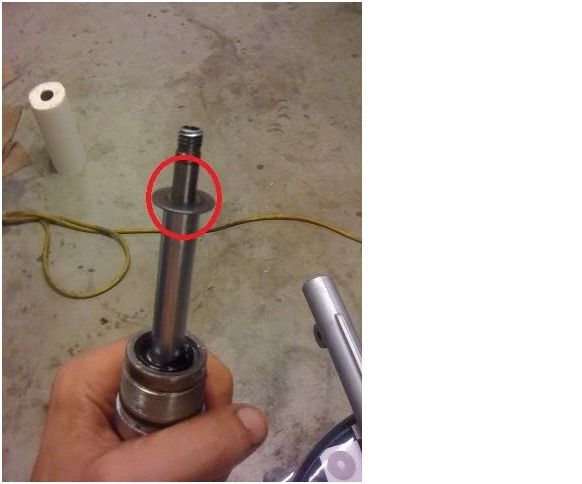

you will then pull it out, empty the oil and remove the shock piston sleeve. put it somewhere safe where it wont get smashed or anything. go ahead and undo the top nut. remember the screw is peened so you will need to get a file and grind ever so little off. then remove nut. removing the night may get a little hard up top but just keep on unscrewing, its okay.

now pull off the shim stack. the shim stack consists of MANY very very thin shims. and you MUST NOT LOOSE THE ORDER OF THE SHIMS! i cannot stress that enough.

you will then pull it out, empty the oil and remove the shock piston sleeve. put it somewhere safe where it wont get smashed or anything. go ahead and undo the top nut. remember the screw is peened so you will need to get a file and grind ever so little off. then remove nut. removing the night may get a little hard up top but just keep on unscrewing, its okay.

now pull off the shim stack. the shim stack consists of MANY very very thin shims. and you MUST NOT LOOSE THE ORDER OF THE SHIMS! i cannot stress that enough.

okay the shims on the TOP of the piston are the rebound shims. usually these dont need to be messed with especially if you have rebound adjustment. unless your shock is super springy and sends you into nose dives like mine used to. in a nut shell, adding shims will make it rebound slower. rule of thumb: slower riders enjoy a slower rebound. faster riders enjoy a faster rebound

okay the shims on the TOP of the piston are the rebound shims. usually these dont need to be messed with especially if you have rebound adjustment. unless your shock is super springy and sends you into nose dives like mine used to. in a nut shell, adding shims will make it rebound slower. rule of thumb: slower riders enjoy a slower rebound. faster riders enjoy a faster rebound

okay now that we have settled that. remove the piston and you will find another shim stack. keep them in order. below the shim stack is a big metal plate. the thickness of like 20 or 30 shims. this plate must remain on the shaft. you can take it off to clean it but remember to put it back as the first washer

okay now that we have settled that. remove the piston and you will find another shim stack. keep them in order. below the shim stack is a big metal plate. the thickness of like 20 or 30 shims. this plate must remain on the shaft. you can take it off to clean it but remember to put it back as the first washer

okay a compression shim stack should look like this.

okay a compression shim stack should look like this.

shims have 2 different overall thicknesses. a .10 and a .15. use a caliper to measure them and figure everything out. now heres the shim stack i personally use. im a 145lb intermediate (on big bikes) rider. i ride pitbikes pretty hard and fast so my stack is rather stiff for my weight. riders up to 170 may be fine with this stack. heres an example shim: 26x15. the 26 means the shim is 26mm wide and .15 thick. so heres my stack

compression:

28x15

26x15

24x15

23x15

21x10

21x10

18x10

18x10

the smaller shim will sit on the first plate on the shaft. end with the bigger shim and put the piston on top of that. just a note: my stock stack was initially 26x15 and 24x15 which is stupid soft. rule of thumb: more shims means thicker. less shims means softer. so if you want a softer ride then ditch some shims. and shims always taper. compression shim starts small and ends big to the piston. rebound starts big on the piston and tapers to small on the nut. now heres my rebound stack

rebound:

26x15

23x15

21x15

17x15

my rebound at first was way too springy. sending me into nose dives every time i caught air. it first had 26x15 and 23x15 which needed more shims to slow down the rebound and make it so i didnt nose dive everything.

figure out what your gonna do and make sure the shims always taper. dont add odd sizes like this

25x15

24x15

23x15

15x15

thats gonna really mess you up. taper down by 2mm and 3mm at the biggest. i try to taper in 1mm inciments but iran short on shims for this build. go ahead and fill your shock body with oil about 2/3 of the way full. remember if you have clickers than set to FULL SOFT. important that you remember this. put the piston and shaft (with tightened nut) into the shock body and press down. its gonna be pretty difficult but be a man and keep pushing till its all the way in. then pull it out (which is about twice as hard and if you pull too fast then it will suction and pull down so go slowly) push in and pull out probably 10 times to remove all the air you can. its okay to have SOME. as you will be filling this shock with air or nitrogen and nitrogen is like 87% air anyways. button everything back up and as your screwing the shock seal and holder in, oil should be overflowing out. you want this. tighten everything nice and tight and your shock should be fully collapsed. go ahead and grab a shock pump and begin pumping. pump in about 50-100 psi untill its shaft has come out completely. then hit it with a minimum of 100psi. i run about 200-225 in my shock and it does pretty well. never exceed 300psi in ANY shock. 225 is even pushing it on my shock. you can run stiffer valving stacks and less psi. i wanted to do this but like i said, i ran out of shims. anyways

shims have 2 different overall thicknesses. a .10 and a .15. use a caliper to measure them and figure everything out. now heres the shim stack i personally use. im a 145lb intermediate (on big bikes) rider. i ride pitbikes pretty hard and fast so my stack is rather stiff for my weight. riders up to 170 may be fine with this stack. heres an example shim: 26x15. the 26 means the shim is 26mm wide and .15 thick. so heres my stack

compression:

28x15

26x15

24x15

23x15

21x10

21x10

18x10

18x10

the smaller shim will sit on the first plate on the shaft. end with the bigger shim and put the piston on top of that. just a note: my stock stack was initially 26x15 and 24x15 which is stupid soft. rule of thumb: more shims means thicker. less shims means softer. so if you want a softer ride then ditch some shims. and shims always taper. compression shim starts small and ends big to the piston. rebound starts big on the piston and tapers to small on the nut. now heres my rebound stack

rebound:

26x15

23x15

21x15

17x15

my rebound at first was way too springy. sending me into nose dives every time i caught air. it first had 26x15 and 23x15 which needed more shims to slow down the rebound and make it so i didnt nose dive everything.

figure out what your gonna do and make sure the shims always taper. dont add odd sizes like this

25x15

24x15

23x15

15x15

thats gonna really mess you up. taper down by 2mm and 3mm at the biggest. i try to taper in 1mm inciments but iran short on shims for this build. go ahead and fill your shock body with oil about 2/3 of the way full. remember if you have clickers than set to FULL SOFT. important that you remember this. put the piston and shaft (with tightened nut) into the shock body and press down. its gonna be pretty difficult but be a man and keep pushing till its all the way in. then pull it out (which is about twice as hard and if you pull too fast then it will suction and pull down so go slowly) push in and pull out probably 10 times to remove all the air you can. its okay to have SOME. as you will be filling this shock with air or nitrogen and nitrogen is like 87% air anyways. button everything back up and as your screwing the shock seal and holder in, oil should be overflowing out. you want this. tighten everything nice and tight and your shock should be fully collapsed. go ahead and grab a shock pump and begin pumping. pump in about 50-100 psi untill its shaft has come out completely. then hit it with a minimum of 100psi. i run about 200-225 in my shock and it does pretty well. never exceed 300psi in ANY shock. 225 is even pushing it on my shock. you can run stiffer valving stacks and less psi. i wanted to do this but like i said, i ran out of shims. anyways

go ahead and assemble the spring and preload rings just like you removed them and you have yourself a new valved shock!!!!!!!!!!

go ahead and assemble the spring and preload rings just like you removed them and you have yourself a new valved shock!!!!!!!!!!

dont go getting into your zoke forks or big bike forks or shock. like i said this is a very different process for those and takes an experienced person to work with and its no joke. also remember that your guessing on your valving shims when you install them. might take a couple times to adjust the shims untill your happy with its performance. this is a money saving secret! unlimited adjustment!

dont go getting into your zoke forks or big bike forks or shock. like i said this is a very different process for those and takes an experienced person to work with and its no joke. also remember that your guessing on your valving shims when you install them. might take a couple times to adjust the shims untill your happy with its performance. this is a money saving secret! unlimited adjustment!

|

|

|